Managing Large Orders – The Challenge:

Manufacturers of high-volume finished goods often face complex despatching challenges. Orders can be too large for a single truck, requiring multiple shipments. High-volume despatches need planning the day before, and different SKUs may need to ship at different times. Add to this the confusion of having a selling unit that differs from your despatching unit, and visibility of remaining quantities can become unclear.

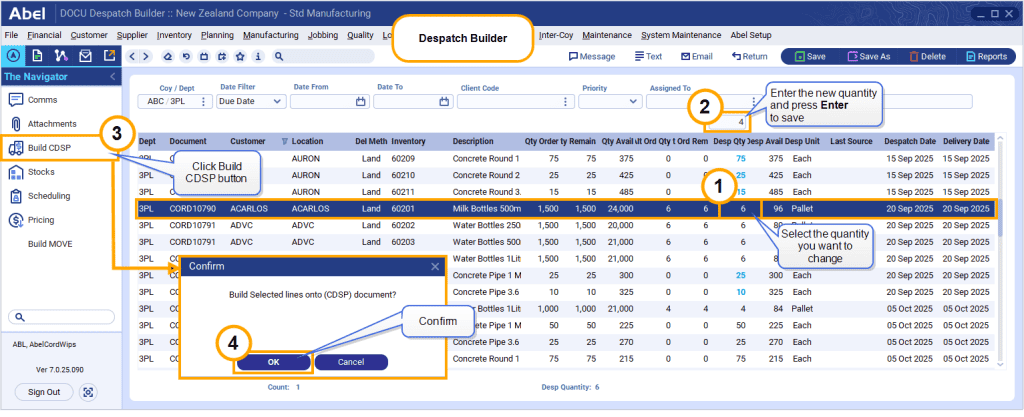

Abel Makes it Simple:

Abel’s Despatch Builder helps you build despatches from customer orders at the line level, using your preferred despatching unit – e.g. pallets or cartons. You can pre-stage stock for next-day despatch, assign priority or pick-up time to a despatch, and manage live despatching on mobile or forklift screens. Sales teams can create orders using the selling unit, while also viewing available stock in the despatching unit. For example, a manufacturer shipping thousands of bottles can split orders into pallets and despatch them in chunks without losing track of what’s left to fulfill on the original order.

The Business Impact:

With Abel, you gain better visibility of stock movements, accurate warehouse data, and seamless invoicing tied to partial despatches. Stock in picking locations stays up to date, enabling high-volume despatching with ease. Planning becomes proactive, despatches are scheduled efficiently, and customers receive their orders on time – even when split across multiple shipments. For industries where volume and speed matter, Abel turns despatching from a pain point into a competitive advantage.