Overcoming Part Shortages and Design Shifts in Manufacturing:

In electronics and engineering, precision and timing are everything. But what happens when materials run short or a part turns out to be unsuitable? These industries often face challenges like sourcing substitute parts, managing BOM revisions, and keeping up with quality control requirements. Whether it’s a supplier delay or a design change, businesses need a reliable way to track changes, manage engineering changes, and maintain production flow without compromising standards.

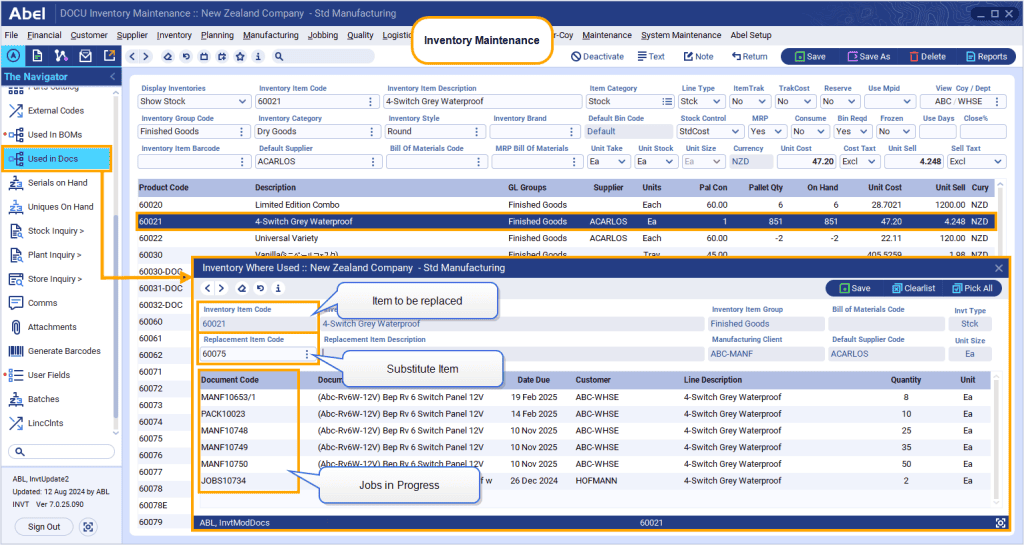

Abels Approach to Streamlined Inventory Substitution:

Abel helps you stay ahead with smart functionality for inventory substitution and BOM management. You can record multiple supplier parts in the Parts Catalog, making it easy to switch when materials run short. If a part needs to be swapped out due to an engineering change, Abel lets you update existing Bills of Materials and manage BOM versions, so nothing gets lost in the shuffle. The “where used” function shows you exactly where a part is used in manufacturing or BOMs and lets you substitute it with just a few clicks. It’s easy to use and supports your quality control and compliance processes.

Stay Agile, Accurate, and Quality-Focused:

With Abel, electronics and engineering businesses gain the flexibility to respond quickly to shortages and design changes. You’ll streamline your processes, maintain product integrity and reduce downtime. Whether you’re managing complex assemblies or high-volume production, Abel helps you stay agile and accurate, so you can focus on innovation, not interruptions.